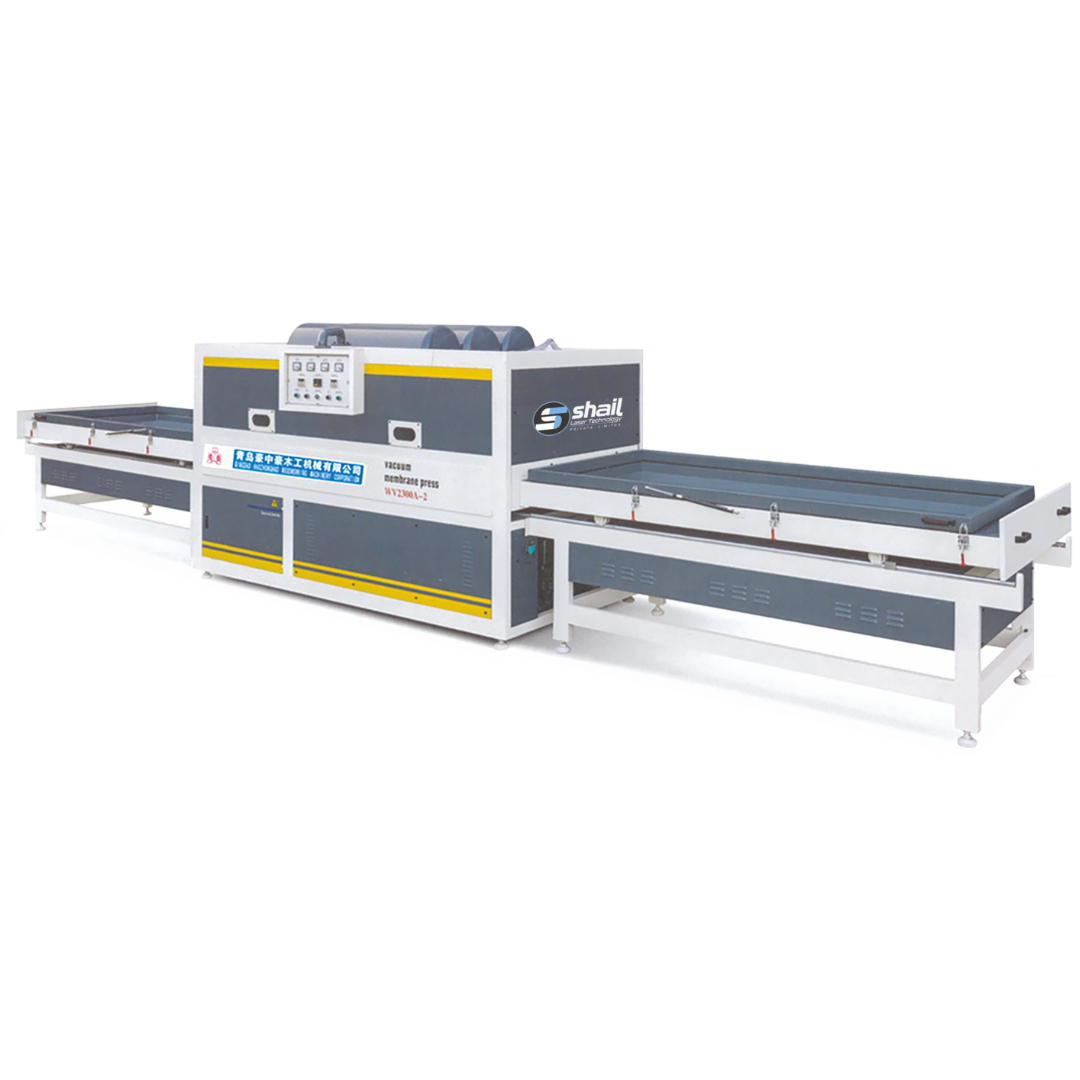

A vacuum membrane press is a specialized machine used in woodworking and furniture manufacturing to apply a uniform and precise pressure on a three-dimensional object or workpiece. The press uses vacuum technology to create a vacuum between the workpiece and a flexible membrane, which is typically made of a heat-resistant silicone or PVC material.

Technical Description:

| DESCRIPTION | UNIT | STV03 | STV03 A+ |

| No. of Working Table | Nos. | 1or2 | 1or2 |

| Work Table Size(L x B) | mm | 2400×1250 | 2400×1250 |

| Max. Thickness of Work Piece | mm | 50 | 50 |

| Max. Connecting Load | kw | 15 | 15 |

| Average Cycle Time | Min. | 3-5 | 3-5 |

| Vaccum | mpa | -0.1 | -0.1 |

| Heating System | – | Heater/Infrared Bulb | Heater/Infrared Bulb |

| Controls | – | Manual/Auto | Manual/Auto |

| Application | – | MDF/HDF/PLY/FLUSH DOOR | MDF/HDF/PLY/FLUSH DOOR/MICA/LAMINATION DOOR |

| Lamination Material | – | PVC Foil | PVC Foil |

| Vaccum Pump | – | German “Busch Make/Indian Pump” | German “Busch Make/Indian Pump” |

| Heating Chamber Insulation | – | No | Yes |

| Trolley Vaccum Control | – | Manual | Manual |

SALIENT FEATURES

-

Energy Efficient Stuctures Design.

-

Vaccum through German Vaccum pump.

-

Automatic Vaccum Controls.

-

Silicon Sheet for Vaccum holding and best quality result.

-

Working trolley designed to accommodate 90″ x 48″ doors.

-

Heating through electric heaters.

-

Centralized Controlling and Display.

-

Digital Temperature Indicator.

-

Robust & Heavy Duty Structure.

-

Single & Double Working Table Arrangement.

-

Faster Your Production.

-

User Friendly & Easy to operate.

-

Membrane door Production.

-

High Temperature Sealing Application.

-

Used for Holding Vaccum to Produce high quality membrane Door.

-

Suitable for temp upto 250 Degree Calceus.