Cold Press

_

Cold presses allow you to press in a stack utilizing cold curing adhesives. They are used for veneering chipboard and MDF panels, laminate panels, doors and more. Cold presses are used in the furniture sector. Whereas hot presses are common in, but not limited to, the marine industry for producing polymer fenders.

Technical Description:

| DESCRIPTION | UNIT | STCP50 | STCP100 |

| Capacity | Ton | 50 | 100 |

| Platen Size | mm | 2500X1300 | 2500X1300 |

| Max Opening | mm | 1000 | 1000 |

| No. Of cylinder | Nos. | 2 | 4 |

| Ram Stoke | mm | 1000 | 1000 |

| Automatic Power Pack&Panel | Hp | 3 | 5 |

SALIENT FEATURES

-

Top and bottom platen designed to generated and handle uniform pressure.

-

Robust & Heavy duty Structure.

-

Auto Pressure Control system to maintain pressure within limit through out pressing cycle.

-

Operation cycle timer.

-

Manual and auto system.

-

Motor Protection Circuit Breaker for motor overload protection.

-

Emergency Stop Arrangement.

OPTIONAL FEATURES

-

Platen Size can be customized as per requirement.

-

Ask for cold press in Different size like 10’X4′,9’X5′,10’X5′,9’X6′,10’X6′,etc.

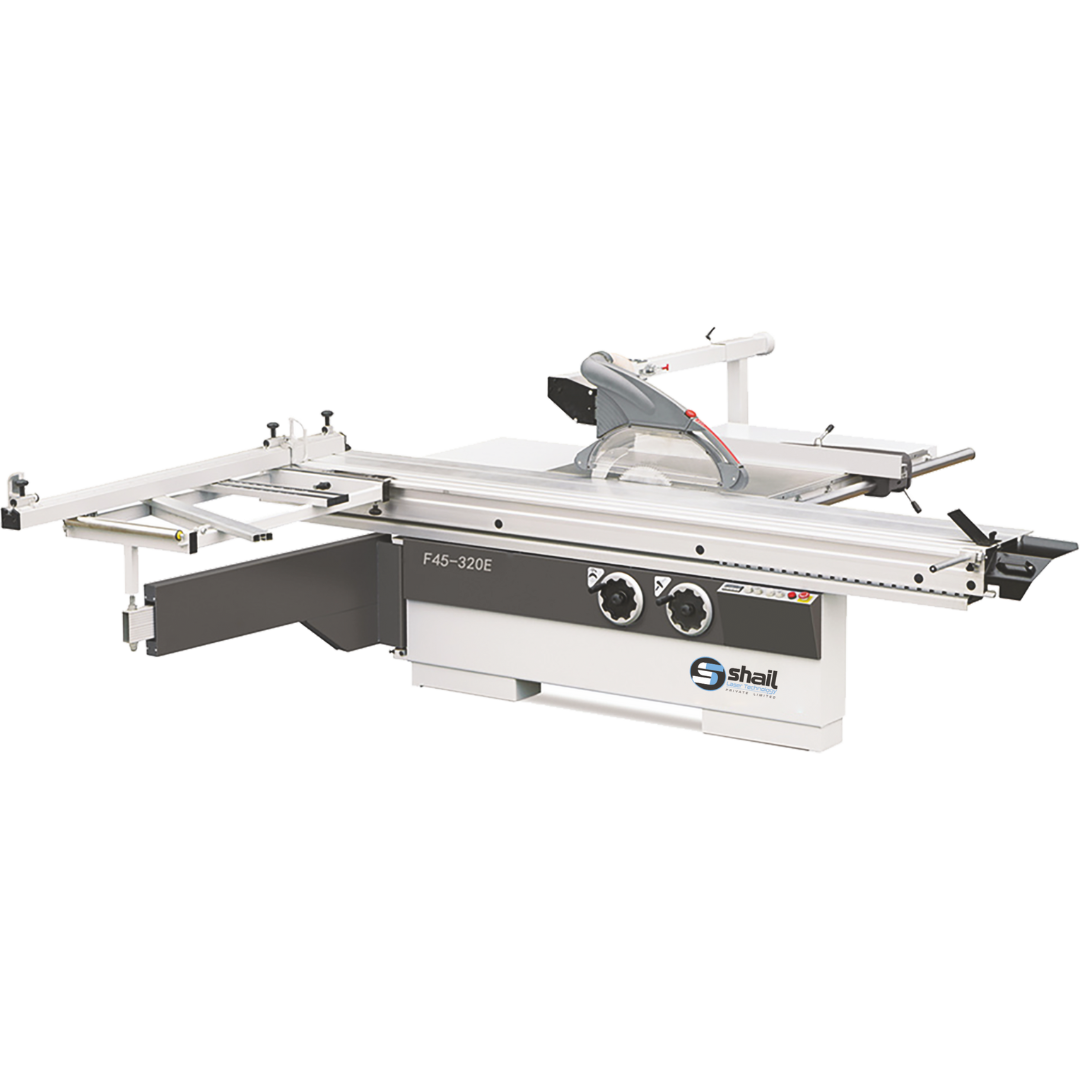

Technical Description:

| DESCRIPTION | UNIT | STPS |

| Sliding Table Size (LxW) | mm | 3200X360 |

| Rip Capacity/Cutting Width | mm | 1250 |

| Main Saw Section | ||

| Saw Blade Diameter | mm | 300(250-350) |

| Shaft Diameter | mm | 30 |

| Tilting of Saw Blade | Degree | 90′-45′ |

| Max. Cutting Depth at 90′ | mm | 80 |

| Max. Cutting Depth at 45′ | mm | 55 |

| Speed Of saw Blade | RPM | 4000/6000 |

| Saw Blade Motor | HP | 7.5 |

| Scoring Saw Section | ||

| Scoring Saw Blade diameter | mm | 120 |

| Shaft Of scoring Saw | mm | 20 |

| Speed of scoring Blade | RPM | 8000 |

| Scoring Blade Motor | Hp | 1 |

SALIENT FEATURES

-

Sturdily built heavy duty machine that gives precise cut with burr free cutting.Robust & Heavy duty Structure.

-

Heavy duty top quality precision sliding table with long lasting accuracy.

-

Easy accessible,user friendly smart touch PLC control panel.

-

Motorized up-down and tilting movement of saw unit from conrol panel.

-

vertical movement of the saw unit is linear with maintanance free guide bearing & allow the whole unit to move easily.

-

Powered ripfence with electrics programmes.

- Central lubricantion system circules lubricant to the required parts of the machine, ensured efficient operation and increase life of parts.

- heavy mitre fence for angular cutting

- All electronic & pneumatic parts are from well-known international brands.

- Low maintenance m/c, esay available cost effective spares, best after sales services support.