Fiber laser metal cutting is an advanced manufacturing process that utilizes a high-powered fiber laser to cut through various types of metals with exceptional precision and speed. The fiber laser generates a concentrated beam of light that is directed onto the metal surface, melting or vaporizing the material along the cutting path.

Technical Description:

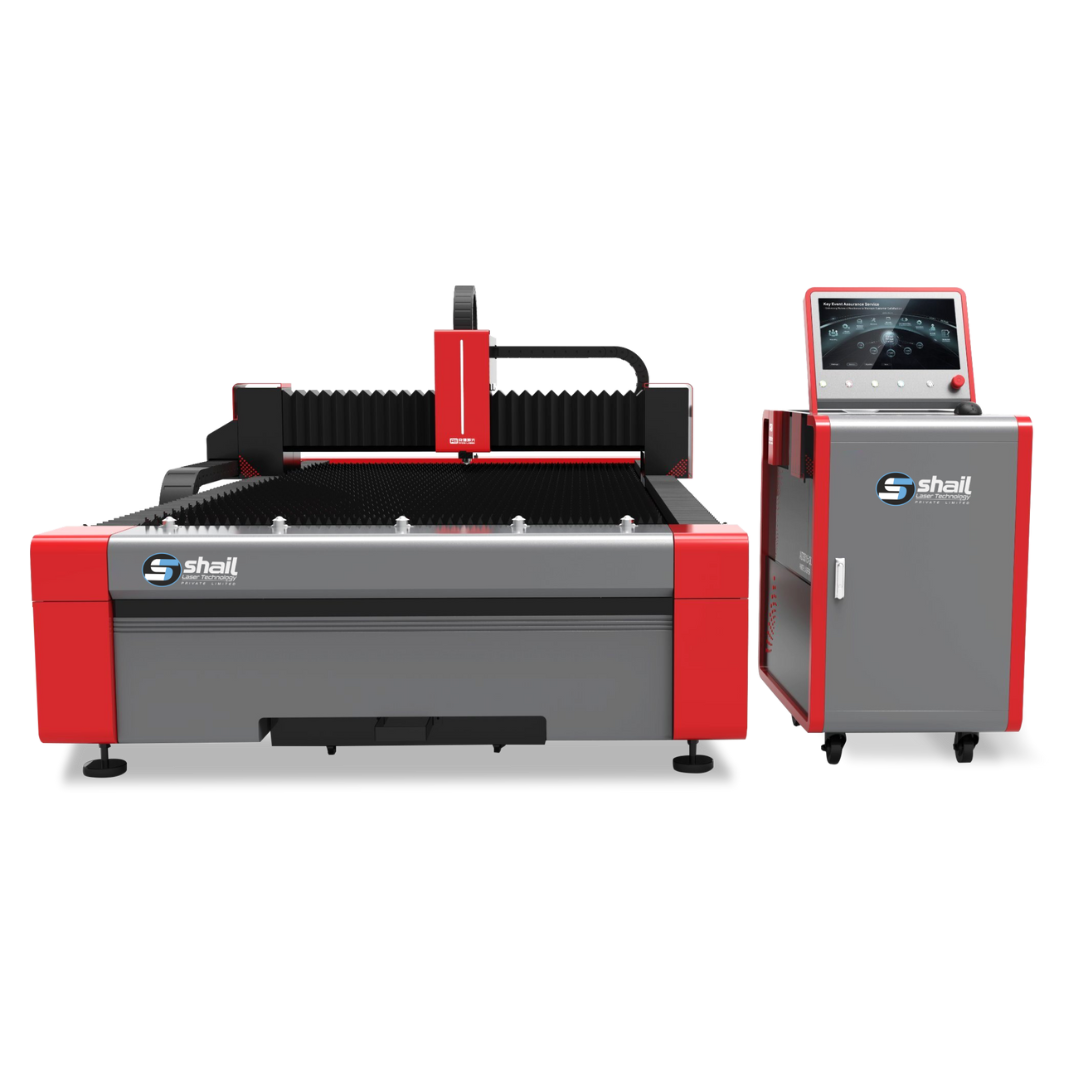

| CONFIGURATION | SLT 3015A |

| Working Area | 3000mmx1500mm |

| Laser Power | 1000w |

| Laser Source | Raycus |

| Laser Head | Raytools |

| Control System | FSCUT 2000 |

| Water Chiller | S&A/Hanli |

| Servo Motor | Japanese Fuji Servo Motor |

| Reducer | Shimpo |

| Guide Rail | HIWIN |

| Rack | YYC |

| Pneumatic Components | Japanese SMC |

| Electronic Components | French Schneider |

| Ball Screw | Taiwan TBI |

| Bearing | Japanese NSK |

| Lubrication System | Automatic |

| Computer | Cantilever Computer |

| Exhaust System | Exhaust Fan |

| Free Wearing Parts | Nozzle(10 sets)Lens(10sets) |

| User Manual | USB |

| Waranty | 2Years |

Technical Description:

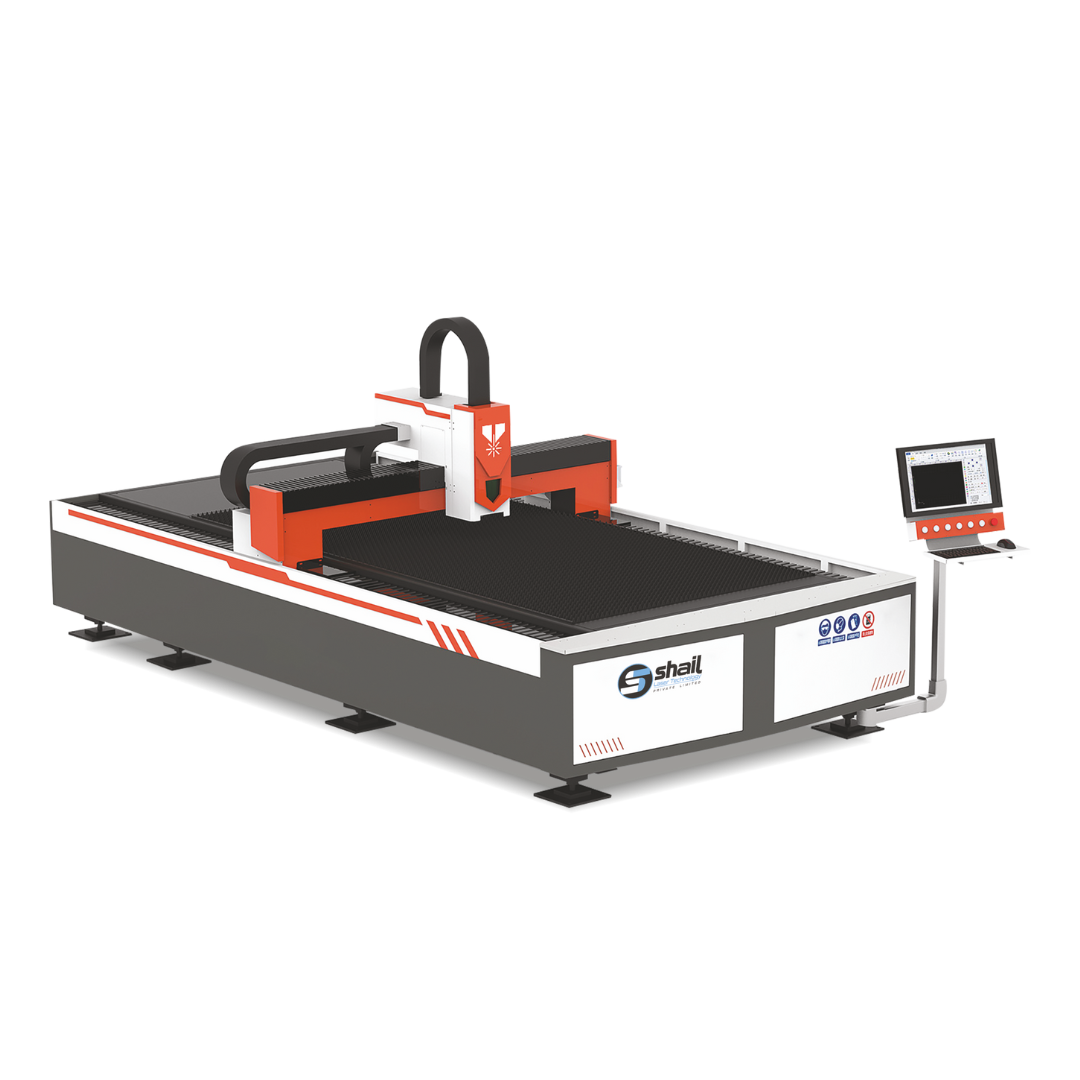

| CONFIGURATION | |||||||||||

| Working Area | 3000mmx1500mm | ||||||||||

| Laser Power | 1000w | ||||||||||

| Laser Source | Raycus | ||||||||||

| Laser Head | Raytools | ||||||||||

| Control System | FSCUT 2000 | ||||||||||

| Water Chiller | S&A/Hanli | ||||||||||

| Servo Motor | Japanese Fuji Servo Motor | ||||||||||

| Reducer | Shimpo | ||||||||||

| Guide Rail | HIWIN | ||||||||||

| Rack | YYC | ||||||||||

| Pneumatic Components | Japanese SMC | ||||||||||

| Electronic Components | French Schneider | ||||||||||

| Ball Screw | Taiwan TBI | ||||||||||

| Bearing | Japanese NSK | ||||||||||

| Lubrication System | Automatic | ||||||||||

| Computer | Cantilever Computer | ||||||||||

| Exhaust System | Exhaust Fan | ||||||||||

| Free Wearing Parts | Nozzle(10 sets)Lens(10sets) | ||||||||||

| User Manual | USB | ||||||||||

| Waranty | 2Years | ||||||||||